Sandwich core laminates can be used to stiffen various fiberglass applications such as boat hulls, storage tanks etc.

-

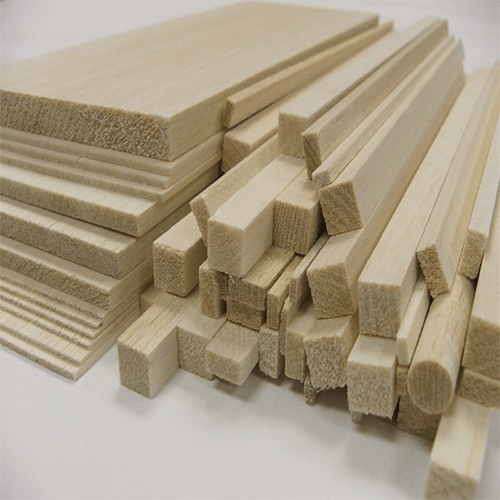

Balsa wood remains one of the most popular core materials in the industry, thanks to its moderate strength and affordability over PVC and honeycomb.

-

KKK offers durable and lightweight honeycomb core panels optimal for structural applications.

-

KKK offer a variety of certified marine grade plywood for boat building and projects that require excellent water-resistant quality.

-

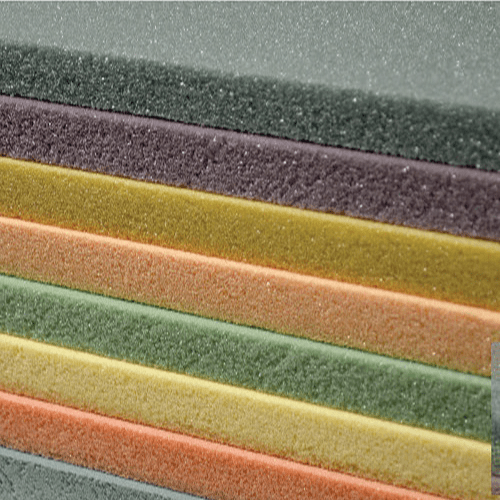

KKK's PU foam consists of a 2-component-system known as A & B for the production of closed cell rigid foam. It has excellent thermal properties and is widely used for insulation of tanks.

-

Rigid Polyurethane Foam can be used in commercial and industrial applications within the service temperature range of -183°C to +105°C. These applications include insulation of pipes, tanks, fittings inside containers, trucks, boats as well as for architectural and structural panels as a core material.