Other related products such as Aerosil Powder, Accelerator, Acetone, Poly Urethane Foam (Sheet & Liquid), Styrene Monomer, Adhesives, Compounds, Waxes & other Releasing Agents such as PVA are all available in our warehouse as a One Stop Shop. All products have been tested against our local conditions and approved for application.

-

Promoter is used for accelerating the room temperature cure of MEKP catalyzed unsaturated polyester resins and vinyl ester resins.

-

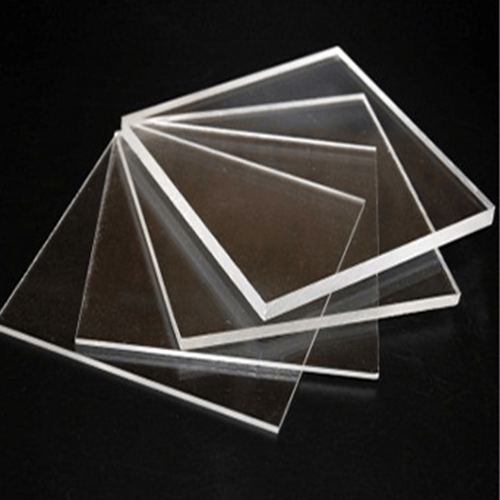

KKK offers marine grade acrylic sheets which is an excellent choice for boats to handle high impact resistance and conditions of the marine environment.

-

Aerosil can be used for altering the properties of resin to change thixotropy, add viscosity, or increase bond strength. It also helps prevent draining from glue joints or on vertical surfaces. Aerosil can be used in combination with other fillers to improve working properties and minimize draining with polyester and epoxy resins.

-

KKK's PU foam consists of a 2-component-system known as A & B for the production of closed cell rigid foam. It has excellent thermal properties and is widely used for insulation of tanks.

-

Polyvinyl Alcohol (PVA) can be used as an air-barrier on top of catalyzed polyester resin/ gelcoat without wax to allow a proper, tack-free cure.

-

Rigid Polyurethane Foam can be used in commercial and industrial applications within the service temperature range of -183°C to +105°C. These applications include insulation of pipes, tanks, fittings inside containers, trucks, boats as well as for architectural and structural panels as a core material.

-

The addition of styrene in amounts of up to 50% helps to make the resin easier to handle by reducing its viscosity.

-

Talc is applied on most body fillers added for fairing and smoothing the finish of fiberglass laminations. It provides opacity, film reinforcement, anti-cracking and barrier properties as part of a surface layer.